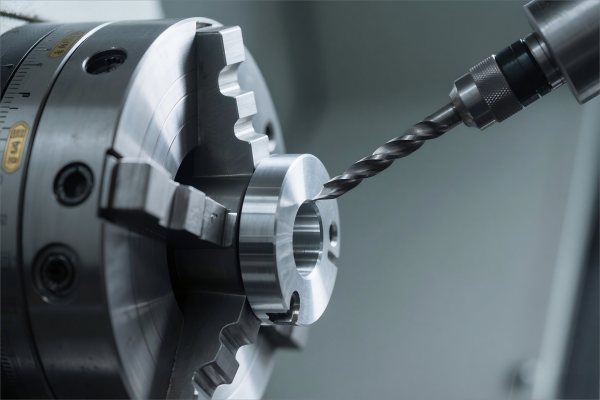

Selecting reliable CNC services is critical for businesses in industries like aerospace, automotive, and medical manufacturing. Computer Numerical Control (CNC) services involve precision machining to produce high-quality parts, but choosing the wrong provider can lead to costly mistakes.

1. Skipping Due Diligence on Provider Credentials

One of the biggest mistakes in sourcing CNC services is failing to verify a provider’s credentials. Reputable providers should hold certifications like ISO 9001 or AS9100 🛠️, which ensure quality management and industry compliance. Check for National Institute for Metalworking Skills (NIMS)-certified machinists on staff. Review their portfolio for experience with your specific materials, such as titanium or composites. Without due diligence, you risk partnering with providers lacking the expertise needed for precision parts.

Table 1: Essential Credentials for CNC Services Providers

|

Credential |

Description |

Why It Matters for CNC Services |

|---|---|---|

|

ISO 9001 |

Quality management system standard |

Ensures consistent part quality |

|

AS9100 |

Aerospace-specific quality standard |

Critical for high-precision industries |

|

NIMS Certification |

Validates machinist skills |

Guarantees technical expertise |

2. Overlooking Material and Machine Compatibility

Not all CNC services providers are equipped to handle every material or machine type. For example, 5-axis machining is required for complex geometries, but not all shops offer it. Similarly, materials like Inconel or carbon fiber require specialized tools and expertise. Failing to confirm compatibility can result in poor surface finishes or damaged parts. Ask providers about their tooling capabilities 📐 and experience with your project’s materials to avoid costly rework.

3. Ignoring Clear Communication Protocols

Effective communication is vital for successful CNC services. Unclear specifications or poor project management can lead to errors in part dimensions or delivery delays. Ensure the provider uses CAD/CAM software to interpret technical drawings accurately. Establish regular updates through project management tools like Trello or direct calls. Providers who fail to clarify tolerances or timelines may deliver subpar results, undermining trust in their CNC services.

4. Choosing Based Solely on Price

Low-cost CNC services often come with hidden risks, such as outdated equipment or inexperienced operators. While budget is important, prioritize value over price. Compare quotes based on quality, turnaround time, and expertise in G-code programming 🧰. Providers offering unrealistically low prices may cut corners, leading to defects or missed deadlines. Request detailed cost breakdowns to understand what’s included and avoid surprises.

Table 2: Price vs. Value in CNC Services

|

Factor |

Low-Cost Provider |

Value-Driven Provider |

|---|---|---|

|

Equipment |

Older, less precise machines |

Modern 3-axis or 5-axis machines |

|

Expertise |

Limited training |

NIMS-certified machinists |

|

Quality Control |

Minimal inspections |

Adheres to ISO standards |

5. Neglecting Quality Control Processes

Quality control is a cornerstone of reliable CNC services. Providers should use Coordinate Measuring Machines (CMM) or laser scanners to verify part accuracy. Ask about their inspection frequency and adherence to ISO 13485 for medical applications. Without robust quality checks, you risk receiving parts that fail to meet tolerance specifications, leading to production delays or safety issues. Always request quality assurance documentation before approving a provider.

6. Underestimating Lead Times and Scalability

Misjudging lead times can disrupt your supply chain. Some CNC services providers overpromise on delivery to secure contracts, only to miss deadlines. Verify their capacity for high-mix, low-volume or large-scale production. Discuss scalability for future orders and their ability to handle rush jobs. Providers with transparent scheduling and ERP systems 📝 ensure timely delivery, enhancing their authoritativeness in CNC services.

7. Failing to Assess Post-Processing Capabilities

CNC services often extend beyond machining to include post-processing like anodizing, heat treatment, or polishing. Not all providers offer these in-house, which can increase costs and lead times if outsourced. Confirm the provider’s capabilities for surface finishing or deburring. In-house post-processing streamlines production and maintains quality control, ensuring trustworthy CNC services.

8. Disregarding Data Security and IP Protection

In CNC services, protecting intellectual property (IP) is critical, especially for proprietary designs. Unsecured file transfers or lax data protocols can lead to IP theft. Choose providers with secure FTP servers or encrypted CAD file sharing. Request Non-Disclosure Agreements (NDAs) to safeguard your designs. Providers with robust cybersecurity measures demonstrate trustworthiness, protecting your business interests.

Table 3: Post-Processing and Security Considerations

|

Consideration |

Description |

Importance for CNC Services |

|---|---|---|

|

Surface Finishing |

Processes like anodizing or polishing |

Enhances part aesthetics and function |

|

Deburring |

Removes sharp edges from machined parts |

Improves safety and quality |

|

Data Security |

Encrypted file transfers, NDAs |

Protects proprietary designs |

9. Not Reviewing Customer Feedback and Case Studies

Customer reviews and case studies provide insight into a provider’s reliability. Check platforms like ThomasNet or Google Reviews for feedback on CNC services. Look for case studies showcasing projects similar to yours, such as precision aerospace components. Providers with positive testimonials and proven success stories demonstrate experience and expertise, reinforcing their authority in CNC services.

Common Industry Problems and Solutions

-

Problem: Inconsistent Part Quality

Variations in part dimensions or finishes disrupt production.

Solution: Partner with ISO-certified providers using CMM for inspections. Request sample parts before full production to verify quality. Regular audits of their processes ensure consistent CNC services. -

Problem: Delayed Deliveries

Late shipments cause supply chain bottlenecks.

Solution: Select providers with ERP systems for transparent scheduling. Agree on realistic timelines and include penalty clauses in contracts to incentivize punctual CNC services. -

Problem: Miscommunication on Specifications

Errors in tolerances or materials lead to defective parts.

Solution: Use standardized CAD/CAM files and confirm specifications in writing. Schedule kickoff meetings to align on project goals, ensuring accurate CNC services.

Conclusion

Navigating CNC services requires careful planning to avoid pitfalls that compromise quality, timelines, or budgets. By verifying credentials, ensuring compatibility, prioritizing communication, and assessing quality control, you can select providers that deliver exceptional results. This guide, grounded in E-E-A-T principles, equips you with the knowledge to make informed decisions, ensuring your CNC services partnerships are reliable and effective. Start evaluating providers today to secure precision manufacturing success.

Glossary of Terms

-

Computer Numerical Control (CNC): Automated machining process using computer-programmed tools to shape parts.

-

ISO 9001: International standard for quality management systems.

-

AS9100: Aerospace-specific quality management standard.

-

5-axis Machining: CNC process allowing tool movement across five axes for complex parts.

-

CAD/CAM Software: Tools for designing parts (CAD) and generating machining instructions (CAM).

-

G-code Programming: Language used to control CNC machine movements.

-

Coordinate Measuring Machine (CMM): Device for measuring part dimensions to ensure accuracy.

-

ISO 13485: Quality standard for medical device manufacturing.

-

Tolerances: Allowable deviations in part dimensions.

-

ERP Systems: Software for managing production schedules and resources.

Authoritative References

-

ThomasNet. (2025). CNC Machining Services: What to Look For in a Provider. https://www.thomasnet.com/articles/custom-manufacturing-fabricating/cnc-machining-services/

-

Protolabs. (2024). How to Choose the Right CNC Machining Service. https://www.protolabs.com/resources/guides/cnc-machining-service-guide/

-

Modern Machine Shop. (2025). Evaluating CNC Service Providers for Precision Manufacturing. https://www.mmsonline.com/articles/evaluating-cnc-service-providers

-

DATRON Dynamics. (2024). Key Considerations for Outsourcing CNC Machining. https://www.datron.com/outsourcing-cnc-machining/