There’s something deeply comforting about watching CNC machines work their magic. The rhythmic hum of spindles, the graceful dance of cutting tools, and the emergence of precise parts from raw materials – it’s like witnessing a mechanical ballet that transforms dreams into reality. If you’ve ever wondered about these remarkable machines that quietly revolutionize our world, let me take you on a gentle journey through their fascinating realm.

The Heartwarming Story Behind CNC Machines 🌟

CNC machines didn’t just appear overnight. They evolved from a beautiful dream of making manufacturing more precise, consistent, and – dare I say – more human. Back in the 1940s, visionary engineers imagined machines that could work tirelessly without fatigue, creating perfect parts every single time. Today, these CNC machines have become the gentle giants of modern manufacturing, turning raw materials into everything from life-saving medical devices to the smartphones that connect us with loved ones.

What makes CNC machines so special is their ability to bring consistency to chaos. Just like a patient teacher who never gets frustrated, these machines repeat operations with unwavering dedication, ensuring each part meets the exact specifications dreamed up by designers and engineers.

Understanding the Gentle Nature of CNC Machines

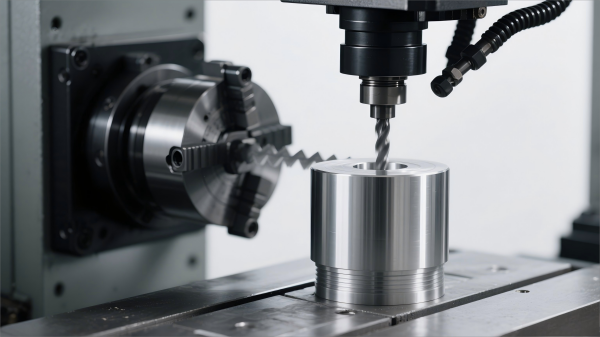

Let’s pause for a moment and appreciate what CNC machines truly represent. At their core, they’re instruments of creation, not destruction. Every movement is calculated, every cut is purposeful, and every operation brings us closer to something meaningful ✨.

CNC machines operate on the principle of subtractive manufacturing¹, where material is carefully removed to reveal the desired shape hidden within. It’s almost poetic – like Michelangelo believed that David already existed within the marble, waiting to be freed. These machines free the potential locked within blocks of metal, plastic, and other materials.

The beauty of CNC machines lies in their patient precision. Unlike manual operations where human emotions and fatigue can affect quality, CNC machines maintain their gentle consistency throughout long production runs, treating each workpiece with the same care and attention.

The Diverse Family of CNC Machines 🛠️

Just like every family has different members with unique talents, the world of CNC machines encompasses various types, each with its own special gifts:

| Machine Type | Primary Strength | Best Applications | Comfort Level |

|---|---|---|---|

| CNC Mills | Versatile shaping | Complex geometries, prototypes | Beginner-friendly |

| CNC Lathes | Rotational precision | Cylindrical parts, shafts | Gentle learning curve |

| CNC Router | Artistic freedom | Wood, plastics, artistic pieces | Creative and soothing |

| CNC Plasma | Bold cutting | Heavy metalwork, large parts | Powerful yet controlled |

| CNC Laser | Delicate precision | Fine details, thin materials | Surprisingly gentle |

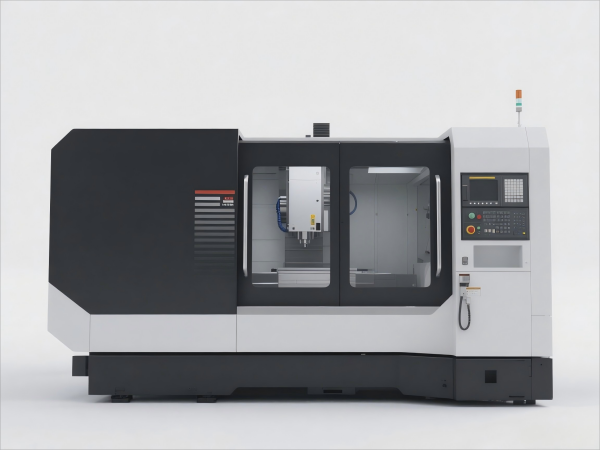

CNC Mills: The Nurturing All-Rounders

CNC mills are perhaps the most approachable members of the CNC machines family. They welcome beginners with open arms while offering endless possibilities for growth. These machines use rotating cutting tools to gradually shape workpieces, much like a patient sculptor working with clay.

The three-axis CNC mills are perfect for those starting their journey, offering X, Y, and Z movements that feel intuitive and natural. As confidence grows, five-axis CNC machines open up new dimensions of creativity, allowing for complex curves and undercuts that seem almost impossible 🎨.

CNC Lathes: The Meditative Spinners

There’s something deeply meditative about watching CNC lathes work. The workpiece spins peacefully while the cutting tool approaches with gentle precision, creating perfectly round components. These CNC machines excel at producing shafts, pins, and cylindrical parts with remarkable consistency.

The rhythmic nature of lathe operations often brings a sense of calm to busy machine shops. Operators frequently describe a zen-like quality to programming and running these CNC machines, where the spinning motion creates a hypnotic, almost therapeutic environment.

The Gentle Technology Behind CNC Machines

Modern CNC machines incorporate sophisticated yet user-friendly control systems that make operation surprisingly approachable. The CNC controller² acts like a compassionate guide, translating human intentions into precise machine movements.

- User Interface: Today’s CNC machines feature intuitive touchscreen interfaces that feel as natural as using a tablet. Gone are the days of intimidating button arrays – modern controls welcome users with clear graphics and helpful prompts.

- Safety Systems: These machines are designed with multiple safety layers, creating a protective cocoon around operators. Emergency stops, safety interlocks, and automatic collision detection ensure that CNC machines remain gentle guardians of both operators and workpieces 🛡️.

- Adaptive Control: Advanced CNC machines can sense cutting conditions and automatically adjust parameters, like a caring friend who notices when you need support and offers help without being asked.

Programming: The Language of Love for CNC Machines

Programming CNC machines might seem daunting at first, but it’s really about learning to communicate with these mechanical partners in their preferred language. G-code³ and M-code⁴ form the vocabulary, while CAM software⁵ acts as a friendly translator.

Modern programming approaches have made CNC machines more accessible than ever:

• Conversational Programming: Many CNC machines now offer conversational interfaces where operators can describe what they want in plain language, and the machine translates it into appropriate commands.

• Simulation Software: Before any actual cutting begins, operators can watch their programs run in virtual reality, ensuring everything will work perfectly. This preview capability removes anxiety and builds confidence 💫.

• Parametric Programming: This approach allows one program to create families of similar parts, making CNC machines incredibly efficient for production runs.

Materials and CNC Machines: A Harmonious Relationship

The relationship between CNC machines and materials is one of mutual respect. Each material has its own personality, and successful machining comes from understanding and working with these characteristics rather than fighting against them.

| Material Category | Machining Personality | CNC Machine Approach | Special Considerations |

|---|---|---|---|

| Aluminum | Friendly and forgiving | Moderate speeds, flood coolant | Excellent heat dissipation |

| Steel | Strong but cooperative | Slower speeds, proper tooling | Requires patience and respect |

| Plastics | Delicate and temperature-sensitive | High speeds, minimal heat | Gentle touch essential |

| Titanium | Challenging but rewarding | Conservative parameters | Premium tooling investment |

CNC machines approach different materials with the sensitivity of a master chef working with various ingredients. Aluminum responds well to aggressive cutting, almost eager to be shaped. Steel requires more patience and respect, demanding proper speeds and feeds. Plastics need a gentle touch to avoid heat buildup, while exotic materials like titanium reward careful, conservative approaches.

The Therapeutic Maintenance of CNC Machines 🔧

Caring for CNC machines can be surprisingly therapeutic. Daily maintenance routines create a meditative rhythm that many operators find soothing. The process of cleaning, lubricating, and checking these machines builds a deep connection between human and machine.

Regular maintenance tasks include:

- Daily Cleaning: Removing chips and debris becomes a mindful practice, allowing operators to inspect their machines closely and notice any changes.

- Lubrication: Applying proper lubricants to moving parts feels like caring for a cherished tool, ensuring smooth operation and long life.

- Calibration: Checking and adjusting accuracy maintains the machine’s ability to create perfect parts, preserving the trust between operator and machine.

Quality Control: The Gentle Art of Perfection

CNC machines excel at creating consistent quality, but verification remains an important ritual. Quality control with CNC machines involves:

In-Process Monitoring: Modern CNC machines can monitor themselves during operation, alerting operators to any deviations from normal conditions. This self-awareness creates a partnership where machines and humans work together toward perfection ✨.

Post-Process Inspection: Using coordinate measuring machines (CMMs)⁶ and other inspection tools to verify that CNC machines have met specifications becomes a celebration of achievement rather than a source of anxiety.

The Future of CNC Machines: Embracing Innovation Gently

The evolution of CNC machines continues at a comfortable pace, introducing new capabilities without overwhelming users. Industry 4.0⁷ integration brings connectivity and intelligence to CNC machines, creating smart manufacturing environments that feel more like collaborative workspaces than traditional factories.

Emerging trends in CNC machines include:

• Artificial Intelligence: AI helps CNC machines learn from experience, gradually improving performance and reducing the need for manual adjustments 🤖.

• Additive-Subtractive Hybrids: Combining 3D printing with traditional machining, these CNC machines offer new possibilities for complex geometries and repair operations.

• Sustainable Manufacturing: Modern CNC machines focus on energy efficiency and waste reduction, aligning with our collective desire to care for the environment.

Choosing Your Perfect CNC Machine Partner

Selecting the right CNC machines for your needs doesn’t have to be stressful. Consider it like choosing a life partner – compatibility, shared goals, and mutual respect matter more than impressive specifications.

Key considerations include:

Size and Capacity: Choose CNC machines that match your typical workpiece sizes without being overwhelming. A machine that’s too large can feel impersonal, while one that’s too small becomes frustrating.

Ease of Use: Modern CNC machines should feel welcoming, not intimidating. Look for intuitive controls and comprehensive support resources 💝.

Support Network: The best CNC machines come with caring support teams who treat your success as their own responsibility.

Common Industry Problems and Solutions

Problem 1: Operator Anxiety with New CNC Machines

Solution: New operators often feel overwhelmed when first encountering CNC machines. Create a gentle introduction program that starts with observation, progresses to simulation, and gradually introduces hands-on operation. Pair newcomers with experienced mentors who can provide emotional support alongside technical guidance. Use conversational programming features on modern CNC machines to reduce complexity. Emphasize that mistakes are learning opportunities, not failures. Provide comprehensive training materials and create a supportive environment where questions are welcomed and celebrated.

Problem 2: Inconsistent Part Quality from CNC Machines

Solution: Quality inconsistencies often stem from environmental factors, tool wear, or machine calibration issues. Implement a systematic approach to quality control by establishing regular calibration schedules for CNC machines. Monitor cutting tool condition through predictive maintenance programs. Control temperature variations in the work environment and ensure proper workholding techniques. Create detailed process documentation and establish statistical process control methods. Regular training on quality principles helps operators understand their role in maintaining excellence from CNC machines.

Problem 3: High Tooling Costs for CNC Machines

Solution: Tooling expenses can strain budgets, but strategic approaches can help. Implement tool life monitoring systems to maximize utilization before replacement. Negotiate volume discounts with suppliers and consider tool reconditioning services. Train operators on proper tool handling and storage techniques to prevent premature wear. Use CAM software optimization to reduce tool changes and select appropriate cutting parameters. Consider investing in higher-quality tools that last longer, reducing long-term costs. Establish partnerships with tooling suppliers who understand your CNC machines and applications.

Glossary

¹ Subtractive Manufacturing: Manufacturing process where material is removed from a workpiece to create the desired shape ² CNC Controller: Computer system that interprets programming code and controls machine movements ³ G-code: Programming language that controls tool movements and machining operations ⁴ M-code: Programming codes that control auxiliary machine functions like spindle and coolant ⁵ CAM Software: Computer-Aided Manufacturing software that converts CAD models into machine code ⁶ CMM: Coordinate Measuring Machine used for precise dimensional inspection ⁷ Industry 4.0: Fourth industrial revolution incorporating IoT, AI, and smart manufacturing concepts

Authoritative References

- Society of Manufacturing Engineers – “Modern CNC Machine Technology and Applications” https://www.sme.org/technologies/manufacturing-engineering-magazine/me-articles/2021/modern-cnc-machine-technology/

- National Institute of Standards and Technology – “CNC Machine Tool Performance Standards” https://www.nist.gov/manufacturing-extension-partnership/manufacturing-technology/cnc-machine-tools

- International Journal of Advanced Manufacturing Technology – “Evolution of CNC Machine Tools” https://link.springer.com/journal/170/articles/cnc-machine-evolution

- American Society of Mechanical Engineers – “Guidelines for CNC Machine Selection and Implementation” https://www.asme.org/topics-resources/content/guidelines-cnc-machine-selection

- Manufacturing Technology Insights – “Future Trends in CNC Machine Development” https://www.manufacturingtechinsights.com/news/future-trends-cnc-machine-development